Jinan, China—Remote today announced comprehensive engineering and material upgrades to its modular home line, marking a quantum leap in performance, longevity, and user comfort for the next generation of container homes. These upgrades encompass the structural shell, enclosure system, mechanical and electrical integration, and interior finishes, and are applicable to its core product lines, including container cabins, container buildings, shipping container buildings, and the company's flagship expandable container homes.

At the heart of these upgrades is a reinforced main frame designed to achieve higher load paths and reduce thermal bridging. Remote's all-new chassis utilizes precision-formed, high-strength steel components with reinforced corner castings and multi-axis bracing. This allows for tighter tolerances in stackable components and minimizes deflection during transport and installation. For multi-unit container buildings, the improved frame geometry increases vertical stacking potential and simplifies the connection of corridor and atrium modules, while maintaining seismic and wind resistance in coastal or high-wind regions.

For its shipping container homes and ocean container cabin models for remote locations, the company has introduced a rapid-leveling foundation system and upgraded connectors. These updates shorten on-site leveling time and allow builders to repair uneven terrain without overdesigning the foundation, speeding up the delivery of container homes in rural or post-disaster areas.

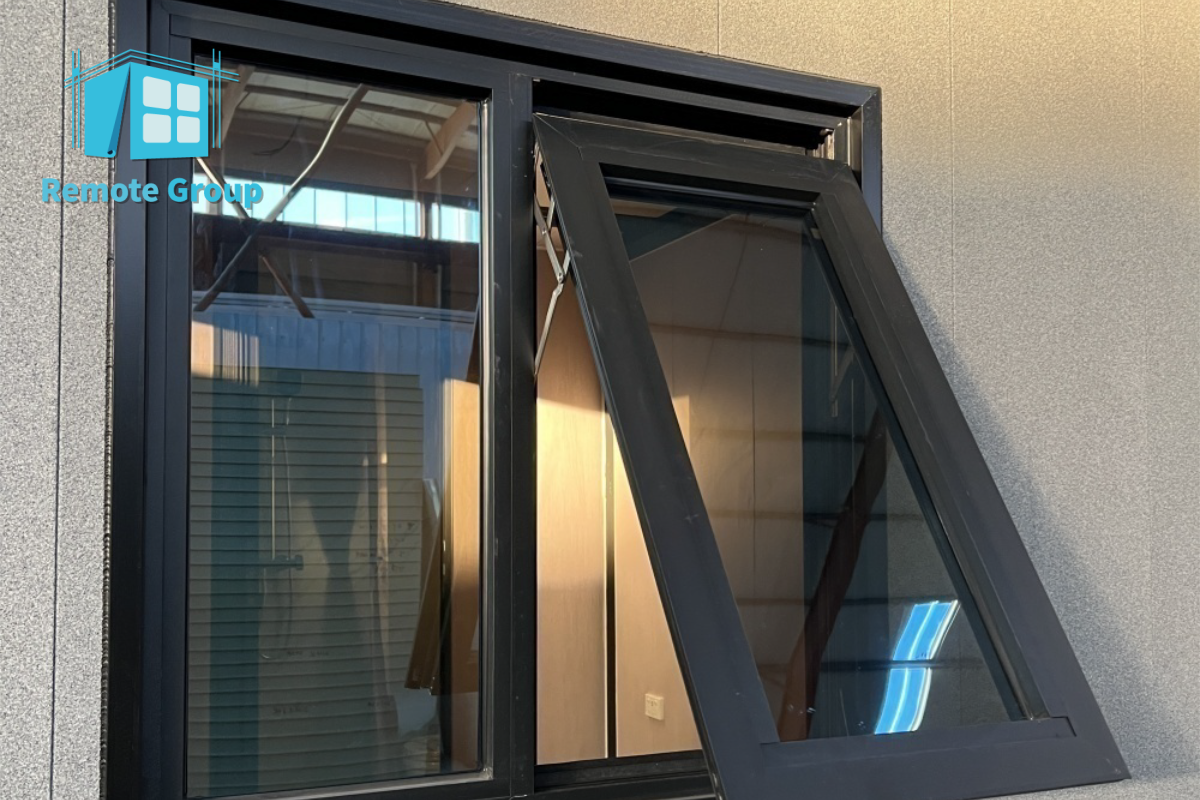

Remote's window and door systems have also made significant leaps forward: insulated frames, argon-filled low-e glass, and multi-point locks are now standard on the premium series. For coastal container buildings, optional marine-grade paint and salt-spray-tested hardware extend their service life in high-exposure environments.

To simplify commissioning, Remote now offers modules equipped with pre-tested electrical and mechanical trunking and color-coded quick-connect manifolds. Heating, ventilation, and air conditioning (HVAC) options include a variable-speed heat pump powered by a low-global warming potential (GWP) refrigerant and a concealed micro-duct box for clean ceiling lines. A new centralized control center supports zoned comfort, indoor air quality (IAQ) monitoring, and demand response integration, making prefabricated container homes more grid-friendly and solar-accessible.

The material upgrade extends to the interior, including formaldehyde-free cabinetry, antimicrobial surfaces in wet areas, and high-wear flooring suitable for commercial traffic. Acoustic underlayment, split partition tracks, and integrated door seals enhance privacy—critical for a comfortable home office setup within a container home. Factory-bonded waterproof membranes and stone composite shower trays in wet areas shorten on-site completion checks.

The lighting design has been upgraded to high-color rendering index, flicker-free drivers with layered scenes (task, ambient, focus) that can be adjusted based on schedule or occupancy. For container homes for sale, Remote offers a curated selection of packages—Minimal, Warm Modern, or Coastal—allowing buyers to balance aesthetics and budget without sacrificing performance.

To meet the growing demand for flexible spaces, the latest expandable container home platforms feature reinforced hinge beams, synchronized actuators, and self-sealing gaskets to maintain an airtight seal when folded. Panels lock with a cam mechanism for rapid deployment, transforming compact shipping spaces into spacious living areas in less than an hour. This approach is particularly attractive to seasonal resorts and event organizers who require fast, repeatable installations.

Lifecycle value is paramount. All modules come with a digital component logbook and QR code for quick maintenance. They are easily removable, making relocation, renovation, and end-of-life recycling more economical. The coating is specially designed to extend the time between repainting, and the wear layer is field-replaceable without damaging the substrate. For institutional buyers evaluating container homes for sale, this means a 20-year reduction in total cost of ownership.

For retail clients and professional developers, these upgrades focus on the most important aspects: structure, envelope, MEP, and durability. Remote focuses on building science that controls comfort and operating costs, rather than superficial cosmetic updates. Whether you're comparing shipping container homes for a lakefront site, evaluating prefabricated container home options for employee housing, or seeking a code-compliant container building for mixed-use infill, the new specifications provide measurable performance and a streamlined installation workflow.

Remote's enhanced product line is available for ordering worldwide, with lead times commensurate with the project size. To inquire about configurations, request stamped drawings, or purchase a container home model tailored to your site and climate zone, contact Remote's Solutions Team. With these technological innovations and material upgrades, the company has set a new benchmark for modern container construction—raising the bar for quality while maintaining modular speed and cost control.